WIPtracker

A MES, WMS, and traceability functionality combined into one real-time WIP Tracking software

Master Every Step of Production with Real-Time WIP Visibility.

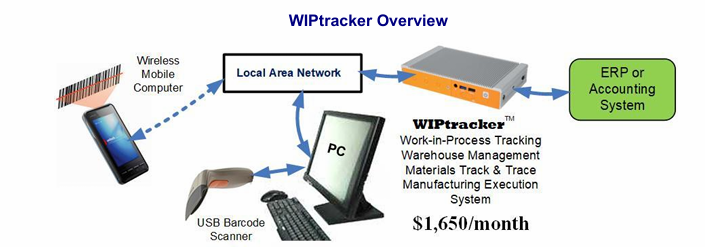

WIPtracker is a fully integrated, real-time work-in-process tracking (WIP tracking), warehouse management, materials tracking, and traceability system designed to give manufacturers complete control over their production and inventory operations. This robust manufacturing execution system (MES) comes pre-installed on a ruggedized Windows IoT (Internet of Things) computer with an integral SQL Server database, making it ready to plug directly into your local area network and begin capturing accurate, real-time data immediately—no complex installation or setup required.

The system includes one mobile computer with a built-in barcode scanner, one USB barcode scanner, and two manager or staff user logins, providing immediate access for key personnel. Additional user and device logins can be added for $50 per month each, while multiple users can share a single data capture computer login at no extra cost. WIPtracker is designed to scale with your operations, ensuring flexible, efficient, and error-free tracking of materials, jobs, and inventory. Plans start at $1,650 per month, giving you a cost-effective solution for real-time operational visibility and control.

Industry Challenges & Solutions

Manufacturing Manual Errors

Challenge: Manual Tracking Processes Leading to Errors and Delays

Many organizations still rely on paper forms, spreadsheets, and manual entry, which are prone to errors and delays in operations.

Our Solution:

WIPtracker automates data capture using barcode scanning, RFID, and weighing scales, eliminating errors and delay.

Labor Shortages and Skilled Worker Deficits

Challenge: Labor Shortages and Skilled Worker Deficits

Manufacturing and warehouse sectors face a lack of skilled workers and labor shortages, increasing costs and reducing overall productivity.

Our Solution:

By automating routine tasks and offering an easy interface for operators with minimal computer skills, saving the labor of 1–3 full-time employees.

Inventory Management and Accuracy Issues

Challenge: Inventory Management and Accuracy Issues

Ensuring inventory accuracy, preventing stockouts or overstocking, and managing demand forecasting remain constant challenges for organizations.

Our Solution:

WIPtracker provides real-time visibility into inventory and order status, uses rules-based tracking, and integrates with ERP systems to maintain accurate data.

Asset Tracking

Challenge: Losing Track of Critical Assets

Manual logs and spreadsheets make it easy for equipment, tools, and containers to go missing, or for calibration dates to be missed, leading to downtime, compliance issues, and inefficiency.

Our Solution:

Track locations, usage, maintenance, and calibration dates in real time using simple barcode scanning, reducing losses, preventing missed calibrations, and keeping operations running smoothly.

Supply Chain Management

Challenge: Supply Chain Disruptions and Integration Challenges

Ongoing risks like delays, elevated costs, and integration with external systems complicate workflows and supply chains consistently every day.

Our Solution:

Using web-services interfaces and Python scripts for ERP and supply-chain data exchange, WIPtracker ensures seamless integration and monitoring daily.

Compliance and Regulatory Management

Challenge: Regulatory Compliance and Traceability Requirements

Maintaining full traceability and documentation is challenging. Incomplete records can lead to failed audits, recalls, or costly compliance issues.

Our Solution:

WIPtracker is CFR 21 Part 11 compliant, giving you full materials traceability and helping you meet strict regulatory requirements with confidence.

Dimensioned Items Tracking

Challenge: Managing Complex, Dimensioned Inventory

Keeping accurate records for varied parts, containers, or custom materials is difficult. Mislabeling or lost items can cause production delays, errors, and wasted resources.

Our Solution:

WIPtracker provides precise tracking for parts, containers, or custom materials, ensuring accurate records, reducing errors, and streamlining your workflow.

Bill of Materials Tracking

Challenge: Managing Complex Bill of Materials

Keeping track of multi-level BOMs across production lines can be confusing and error-prone. Mistakes in components or quantities can lead to production delays, scrap, and costly rework.

Our Solution:

WIPtracker simplifies BOM management by providing real-time visibility into all components and assemblies. Ensure the right parts are used every time, reduce errors, and keep production on schedule.

Key Benefits

WIPtracker provides manufacturers with complete visibility and control over their production processes, from raw materials to finished goods. With real-time work-in-process tracking, serial number traceability, and automated workflows, it ensures quality, compliance, and efficiency on the shop floor. Barcode and RFID data capture, job costing automation, and exception alerts help reduce errors, scrap, and rework, while production scheduling and material tracking streamline operations. Scalable and flexible, WIPtracker supports both on-premise and cloud deployment, empowering manufacturers to optimize productivity, reduce waste, and maintain regulatory readiness.

Unlock ROI Faster

- Rapid Cost Recovery: Achieve payback in months with $6K–$8K in monthly savings per site from reduced labor, fewer errors, and streamlined workflows—from job inception through delivery.

-

Data-Driven Decisions: Real-time dashboards give you instant insight into production throughput, inventory turns, and on-time delivery rates—helping you respond quickly to challenges and opportunities.

-

Scalable Growth: Whether you run a single plant or multiple sites, WIPtracker supports expansion without requiring a costly ERP overhaul.

Built for Complex Operations

Seamless Integrations: Native compatibility with major ERP systems, plus support for custom integrations, ensures smooth data flow across your operations.

Advanced Tracking: From RFID-enabled, contactless monitoring for high-volume assets to detailed tracking of unique materials like rolls and batches, WIPtracker gives you full supply chain visibility.

Compliance Ready: With embedded SQL databases, immutable audit trails, and GS1-standard barcode/RFID capabilities, WIPtracker simplifies compliance with FDA, DOD, and DSCSA requirements.

Error-Proof Processes: Automation reduces human error rates by up to 95%, ensuring accurate material genealogy every step of the way.

Scalable & Supported

From custom-manufacturers to global distributors, WIPtracker grows with your business—powered by BellHawk’s modular design, without the bloat of oversized enterprise systems. KnarrTek’s expert consultants provide tailored setup, ongoing optimization, and 24/7 support to keep your operations running at peak performance.

Proven Impact

WIPtracker consistently delivers measurable gains across industries such as medical devices, pharmaceuticals, food processing, and industrial distribution. One manufacturer cut cycle times by 40% through real-time visibility, turning inefficiencies into opportunities and supply chains into competitive advantages.

Ready to take control of your workflows?

Contact Us Today

to Gain Control and Confidence with WIPtracker.

Interested in Learning More?

Click the button below to access KnarrTek’s Whitepapers by Dr. Peter Green.

KnarrTek's Capabilities

Materials Flow & Job Tracking

Monitor material flow and job progress throughout production.