BellHawk Online

Start Tracking Instantly with Our Inventory Tracking System

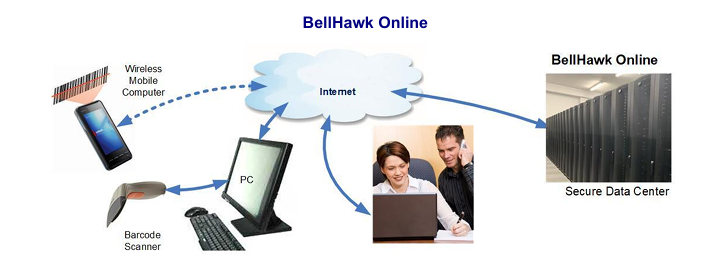

BellHawk Online is a cloud-based inventory tracking system and labor tracking system. Designed for small to mid-sized organizations, it enables real-time visibility into materials and labor activity—all through a secure web browser.

Starting at just $450/month, BellHawk Online runs on a Windows platform, and requires no special equipment or IT setup.

Industry Challenges & Solutions

Manufacturing Manual Errors

Challenge: Manual Tracking Processes Leading to Errors and Delays

Paper logs and spreadsheets cause data entry mistakes, lost records, and operational bottlenecks.

Our Solution:

BellHawk Online uses browser-based barcode scanning on everyday devices to capture data instantly, slashing errors by 90% and speeding up workflows—no training curves for staff.

Labor Shortages

Challenge: Labor Shortages and Skilled Worker Deficits

Short-staffed teams struggle with repetitive tracking tasks, amplifying costs in fast-paced environments.

Our Solution:

Automate data capture through simple barcode scans, enabling short-staffed teams to work faster and more efficiently without added labor costs.

Inventory Management

Challenge: Inventory Management and Accuracy Issues

Scattered stock leads to stockouts, waste, and unreliable counts across locations

Our Solution:

Track containers (boxes, reels, pallets) by barcode with location-specific rules; uses point of action warnings to notify users

Asset Tracking

Challenge: Losing Track of Critical Assets

Manual logs and spreadsheets make it easy for equipment, tools, and containers to go missing, or for calibration dates to be missed, leading to downtime, compliance issues, and inefficiency.

Our Solution:

Track locations, usage, maintenance, and calibration dates in real time using simple barcode scanning, reducing losses, preventing missed calibrations, and keeping operations running smoothly.

Supply Chain Management

Challenge: Supply Chain Disruptions and Integration Challenges

Limited visibility into material flow hinders quick responses to delays or changes.

Our Solution:

CSV export tools for easy data sharing with spreadsheets or basic ERPs; track receipts, moves, and shipments with timestamps for end-to-end audit trails.

Compliance Management

Challenge: Regulatory Compliance and Traceability Requirements

Basic operations risk non-compliance without robust lot/batch tracking.

Our Solution:

Immutable logs for materials genealogy; supports GS1 barcodes and basic FDA/DOD traceability for regulated items like food or pharma precursors.

Simplify Inventory Tracking

BellHawk Online provides barcode-driven tracking for all your inventory—whether it’s boxes, rolls, reels, pallets, or finished goods. By attaching tracking barcodes to each container or asset, your team can easily follow every movement of materials throughout your operations. This includes tracking inventory from receiving and put-away to transfers and final shipment, ensuring complete visibility at every stage.

With BellHawk Online, you’ll always know the exact location of materials across multiple areas or warehouses. The system helps prevent stockouts and waste by providing real-time visibility into on-hand quantities. Because every scan updates your cloud-based records instantly, managers can view accurate counts, movements, and transactions from anywhere. By eliminating manual spreadsheets and paper records, BellHawk Online ensures accuracy, reduces errors, and saves valuable administrative time.

Streamline Labor Tracking

BellHawk Online also simplifies labor data collection by allowing teams to capture actual work time for every job step. Production workers can simply scan a barcode to start or stop a task, automatically logging labor hours to specific jobs or departments. This seamless process eliminates the need for manual time entry and ensures that labor data is captured accurately and efficiently.

The platform makes it easy for managers to monitor labor productivity across shifts and workstations. It tracks time spent on each job, order, or operation, giving insight into where time is used and where improvements can be made. With BellHawk Online, you can reduce reporting delays, eliminate data entry errors, and generate real-time labor efficiency reports that highlight bottlenecks and opportunities for process improvement.

Key Benefits

BellHawk Online gives manufacturers real-time visibility into production, inventory, labor, and materials, helping reduce errors and streamline operations. With barcode data capture, lot and asset tracking, and paperless workflows, it improves accuracy and efficiency across the shop floor. Cloud-based and easy to implement, BellHawk Online delivers fast results, supports regulatory compliance, and scales with your operations, empowering you to make smarter, faster decisions while maximizing productivity and ROI.

Prevent Costly Errors

Automated barcode scanning reduces the risk of human error, ensuring products and materials are tracked correctly every time.

Scalable & Flexible

Whether you’re a small business or a multi-site operation, BellHawk Online can scale to meet your needs without the complexity of a full ERP system.

Expert Support

KnarrTek provides expert consultation and hands-on support to ensure your BellHawk Online system is configured to meet your unique needs.

Ready to take control of your workflows?

Contact Us Today

to experience the power of BellHawk Online.

Interested in Learning More?

Click the button below to access KnarrTek’s Whitepapers by Dr. Peter Green.

KnarrTek's Capabilities

Materials Flow & Job Tracking

Monitor material flow and job progress throughout production.