Textile Manufacturing Traceability Software for Production and Inventory Visibility

5 Game-Changing Strategies to Boost Visibility, Slash Inventory Waste, and Accelerate Your Operations

Revolutionize Your Textile Ops: Textile Manufacturing Traceability Software

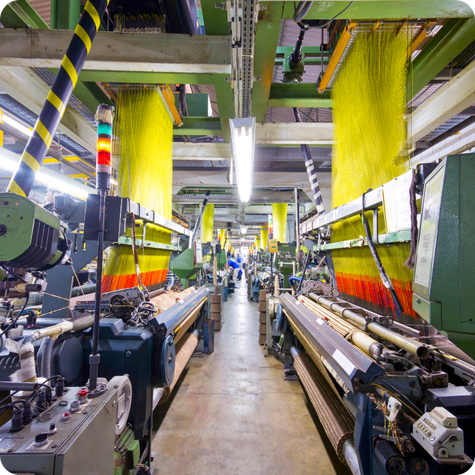

Textile manufacturers operate complex, high-volume environments that span raw material sourcing, yarn production, weaving and knitting, dyeing and finishing, warehousing, and distribution. Managing fibers, dyes, fabrics, and finished goods requires tight coordination across production schedules, quality requirements, and customer commitments. Without centralized visibility, many textile operations rely on spreadsheets, disconnected systems, and manual recordkeeping, which can slow decision-making and increase the risk of waste, errors, and delays.

KnarrTek’s BellHawk and MilramX platforms provide textile manufacturers with software tools for material traceability, work-in-process tracking, asset visibility, and workflow coordination. These platforms support textile operations across apparel, home textiles, technical fabrics, nonwovens, and industrial textile applications. By digitizing tracking activities and consolidating operational data, manufacturers gain clearer insight into inventory levels, production status, and process flow across manufacturing stages.

BellHawk supports real-time tracking of fibers, yarns, dyes, fabrics, and production activity using barcode and RFID-based data capture—including advanced roll conversion capabilities that seamlessly manage the transformation of large fabric rolls into cut pieces, sewn components, or custom widths while maintaining precise lot-level traceability for quality assurance and compliance. MilramX extends this foundation by enabling workflow automation and data integration across ERP systems, production planning tools, quality processes, and supply chain applications. Together, BellHawk and MilramX help centralize information, reduce manual data entry, and support consistent documentation throughout the textile production lifecycle.

Flexible Deployment Options for Diverse Textile Manufacturing Environments

Textile manufacturers operate in a wide range of physical and technical environments, from centralized mills to distributed finishing operations and multi-site supply networks. KnarrTek’s solutions are designed to adapt to these conditions without disrupting ongoing production processes.

On-Premise Deployment for Internal Data Control

BellHawk and MilramX can be deployed on internal servers for manufacturers that prefer to manage their systems within existing IT environments. On-premise deployments allow organizations to maintain direct oversight of data while still leveraging core tracking, reporting, and automation capabilities.

This approach is often suited for manufacturers with proprietary processes, established legacy systems, or internal policies around data hosting and access.

Offline Data Capture for Production Floor Continuity

Textile production areas may experience inconsistent network connectivity due to facility layout, environmental conditions, or mobile operations. BellHawk supports offline data capture on supported mobile devices, allowing operators to scan materials, record production steps, and update status information without interruption.

Captured data is synchronized once connectivity is restored, helping ensure traceability records remain accurate and complete.

Hybrid Configurations for Multi-Facility Visibility

Hybrid deployments allow textile manufacturers to collect data locally on production floors while sharing consolidated views across departments and locations. Planners, quality teams, and leadership can access unified dashboards that reflect activity across facilities, product lines, and suppliers while accommodating local infrastructure constraints.

BellHawk Capabilities for Textile Manufacturing Operations

Turbocharge Production & WIP Tracking

BellHawk enables textile manufacturers to track materials and orders from raw material intake through spinning, weaving or knitting, dyeing, finishing, packaging, and shipment. Visibility into work-in-process helps teams identify bottlenecks, coordinate handoffs between production stages, and better understand current job status.

Materials Traceability and Inventory Management

BellHawk supports traceability for raw materials such as fibers, yarns, dyes, and chemicals across storage, production, and outbound logistics. Manufacturers can view material status including on hand, allocated, in process, or shipped, supporting inventory accuracy and planning efforts.

Asset, Tool, and Equipment Tracking

Textile operations rely on shared equipment such as looms, spinning frames, dyeing vessels, and inspection tools. BellHawk can track the location and status of these assets to support scheduling, availability awareness, and maintenance planning.

Barcode and RFID Tracking Technology

BellHawk integrates barcode and RFID technologies to support faster and more accurate data collection. Scanning rolls, batches, and containers helps reduce manual entry and supports timely updates across connected systems.

MilramX: an Automation and Integration Software for Decision Support

MilramX enhances BellHawk by enabling workflow automation, rules-based actions, and system integrations. This layer helps textile manufacturers coordinate processes and reduce reliance on manual oversight.

Rules-Based Alerts and Workflow Automation

Manufacturers can configure notifications for conditions such as inventory thresholds, production delays, or quality exceptions. Automated workflows can support standardized steps such as approvals, material movements, or status updates, helping reduce variability in execution.

Data Visibility for Project and Operations Leadership

MilramX consolidates data from multiple sources to provide operational views into throughput, yields, and production trends. These insights support planning, performance reviews, and continuous improvement initiatives.

ERP, Project Management, and Scheduling Integration

MilramX integrates BellHawk data with ERP systems, MES platforms, quality tools, and other enterprise applications. This connectivity reduces duplicate data entry and helps align shop-floor activity with broader business processes.

Addressing Common Textile Manufacturing Challenges

Textile manufacturers often face operational challenges driven by fragmented visibility across production facilities, warehouses, and supplier networks. When materials, work-in-process, and finished goods are tracked in disconnected systems or through manual methods, it becomes difficult to understand true inventory positions, production status, and resource availability in real time. These visibility gaps can result in material shortages, excess inventory, delayed production decisions, and increased effort spent reconciling data across departments.

Manual data collection and paper-based tracking further compound these issues by introducing errors and slowing response times when production conditions change. As textile supply chains grow more complex and customer expectations for accuracy, consistency, and responsiveness increase, maintaining reliable traceability and documentation becomes more challenging. Teams responsible for production, quality, planning, and logistics often operate with partial or outdated information, making coordination more difficult and increasing the risk of misalignment.

BellHawk and MilramX help address these challenges by centralizing operational data and supporting consistent, digital tracking practices across textile manufacturing environments. BellHawk provides clear visibility into materials, work-in-process, production activity, and equipment usage as items move through spinning, weaving or knitting, dyeing, finishing, and distribution. MilramX builds on this foundation by enabling workflow automation, system integrations, and shared reporting that help align teams around the same set of information.

Together, these platforms reduce the need for manual reconciliation, improve data accuracy and reliability, and support more timely, informed decision-making across departments. By replacing fragmented tools with a unified approach to traceability and operational visibility, textile manufacturers can better manage complexity, improve coordination, and maintain greater control as operations scale.

Limited Visibility Across Production Stages and Facilities:

Without centralized tracking, textile manufacturers often struggle to see where fibers, yarns, fabrics, and work-in-process reside across spinning, weaving, dyeing, and finishing operations. BellHawk provides a single source of operational visibility that improves coordination across departments and locations.

Manual Tracking and Process Inefficiencies:

Spreadsheets and paper logs increase administrative effort and introduce errors in textile production environments. BellHawk’s automated tracking reduces manual data entry and helps improve accuracy across inventory, production status, and material movements.

Coordination Between Production, Quality, and Supply Chain Teams:

Real-time updates help ensure that production, quality, warehousing, and planning teams work from the same information. Shared visibility reduces miscommunication, supports smoother handoffs between processes, and helps minimize delays.

Documentation and Traceability Requirements:

Textile manufacturers often need consistent records for quality review, internal audits, and operational accountability. BellHawk and MilramX support digital traceability and documentation without relying on manual recordkeeping, helping maintain organized and accessible production histories.

KnarrTek: Streamlining Execution

Summary Capabilities for Textile Manufacturers

With BellHawk and MilramX, textile manufacturers can:

Track raw materials from receipt through processing and finishing

Monitor work-in-process and production status in near real time

Align inventory levels with production plans and demand signals

Generate reports to support quality reviews and internal audits

Enable consistent labeling and batch identification

Improve collaboration between production, quality, and supply chain teams

These capabilities help manufacturers reduce errors, improve workflow coordination, and maintain operational clarity across expanding textile operations.

BellHawk and MilramX are designed to scale with textile manufacturers as operations evolve from smaller production runs to larger, multi-site environments. The platforms are built to accommodate increased production volumes, additional product lines, and more complex workflows without requiring disruptive changes to existing processes or systems. This flexibility allows manufacturers to grow while maintaining continuity across operations.

As production expands, improved traceability and work-in-process visibility become essential for managing complexity. BellHawk helps manufacturers maintain clear insight into materials, production activity, and inventory status across facilities, while MilramX strengthens connectivity between systems and teams. Together, these capabilities support faster response to operational changes, more consistent execution, and better alignment across departments.

By strengthening data connectivity and standardizing tracking practices, BellHawk and MilramX help textile manufacturers support sustainable growth with greater control and confidence. As business demands shift and operations scale, these platforms provide a stable foundation for improved coordination, operational clarity, and informed decision-making across the organization.

Ready to improve visibility and control across your textile operations?

Click the button, complete the form, and learn how BellHawk and MilramX can support your manufacturing environment.

Interested in learning more? Click the button below to access KnarrTek’s Whitepapers by Dr. Peter Green.

Explore KnarrTek's Core Capabilities

Real-Time WIP Tracking

Gain real-time visibility into engineering project progress across offices, fabrication shops, warehouses, and job sites.

Inventory & Asset Tracking

Track materials, tools, and equipment across multiple locations to support efficient project execution.

RFID Inventory System

Automate data capture to reduce manual entry and improve accuracy across engineering operations.

Track & Trace Materials

Maintain end-to-end traceability from material receipt through installation and project closeout.

Materials Flow & Job Tracking

Monitor material flow, work status, and task progression throughout the full engineering project lifecycle.