SmartOps24x7

Manufacturing Operations Management Software & Intelligent Agent Platform

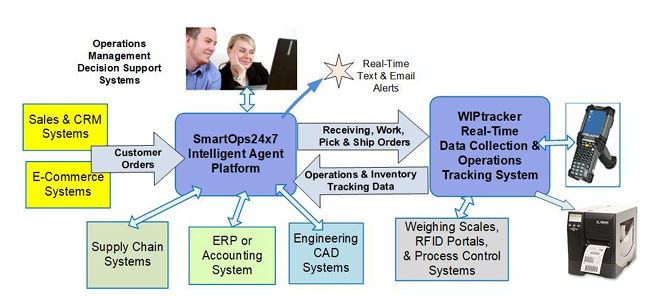

The purpose of SmartOps24x7™, our flagship Smart Operations Management Software, is to enable industrial organizations to track and manage the flow of jobs and materials in real-time through manufacturing plants, distribution warehouses, delivery, field, and installation operations. Pronounced “Smart Ops 24 by 7,” SmartOps24x7 uses real-time intelligent agents to automate the “intelligent grunt work” that managers and staff otherwise waste time on—tracking operations with paper forms, Excel spreadsheets, reading yesterday’s reports, entering duplicate data, and attending endless meetings.

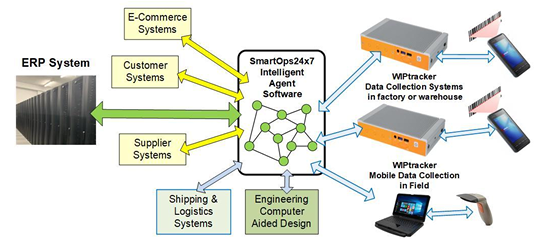

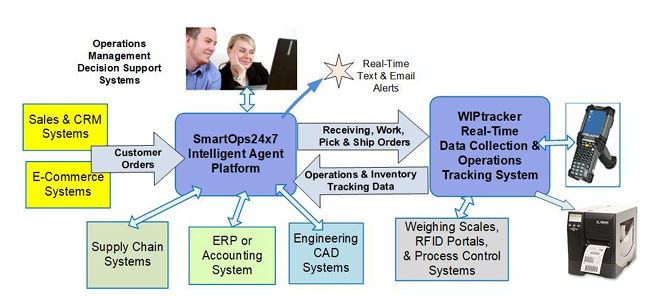

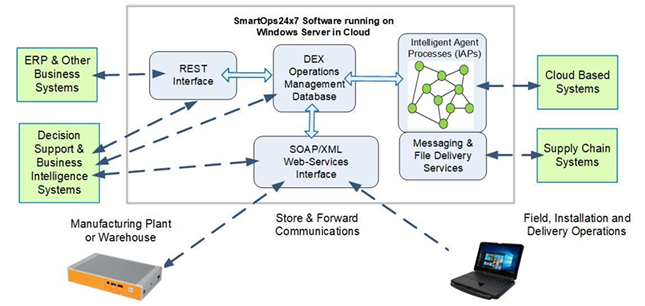

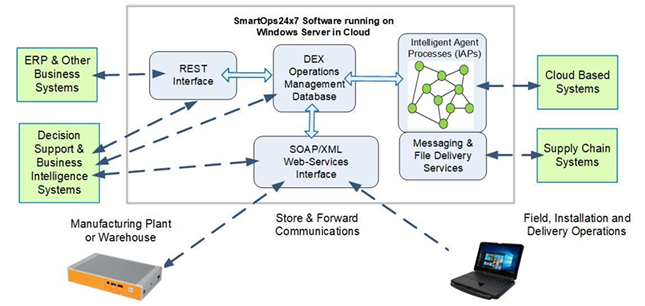

As an IIoT-Enabled ERP Enhancer and Real-Time Workflow Automation System, SmartOps24x7 runs on a Windows Server in the Cloud or your data center, linking front-office operations with shop floor, warehouse, and field activities. Data is collected via WIPtracker™ IIoT computers at sites or ruggedized mobile devices for field collection. It enhances ERP systems by managing customer orders through engineering design, materials procurement, manufacturing, distribution, shipping, logistics, delivery, and installation.

SmartOps24x7 is versatile, fitting multiple industry-standard labels to highlight its comprehensive capabilities:

Smart Operations Management Software Manufacturing Operations Management (MOM) Suite

Intelligent Agent-Based Operations Platform Real-Time Workflow Automation System

Supply Chain Visibility & Traceability Platform IIoT-Enabled ERP Enhancer

AI-Driven Operations Intelligence Tool Field & Remote Operations Optimizer

Industrial Digital Transformation Platform

Industry Challenges & Solutions

Manual Tracking and Data Duplication Wasting Time

Challenge: Manual Tracking and Data Duplication Wasting Time

Managers and staff spend hours on paper forms, spreadsheets, and duplicate data entry across systems, leading to errors and delays in operations visibility.

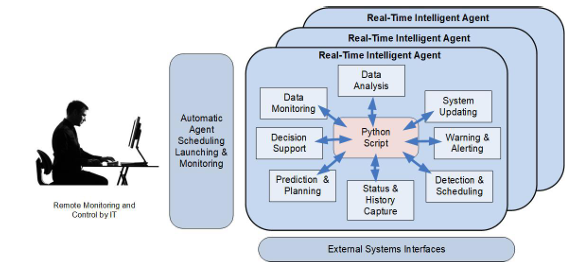

Solution: Intelligent Agents for Automated Real-Time Monitoring

SmartOps24x7 agents run 24×7, monitoring data from multiple sources, interpreting it into actionable information, updating systems automatically, and sending email alerts for issues—eliminating grunt work and providing instant visibility as an AI-Driven Operations Intelligence Tool.

Unreliable Internet in Remote or Field Operations

Challenge: Unreliable Internet in Remote or Field Operations

Field, delivery, and installation teams struggle with data capture where connectivity is spotty, causing delays in syncing and real-time decision-making.

Solution: Store-and-Forward Technology with WIPtracker

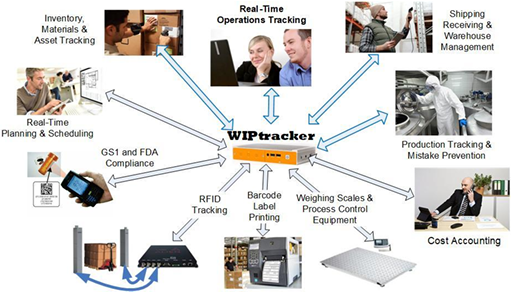

WIPtracker IIoT boxes and mobile software use store-and-forward communications to capture data offline, syncing automatically when connected—ensuring continuous operations even without reliable Internet, ideal as a Field & Remote Operations Optimizer.

Lack of Traceability in Regulated Industries

Challenge: Lack of Traceability in Regulated Industries

In food, pharmaceuticals, and medical device manufacturing, tracking materials from suppliers to end products is manual and error-prone, risking compliance failures.

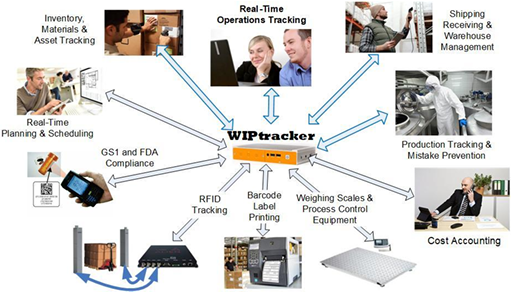

Solution: Automated Traceability with Barcode/RFID and EPCIS/EDI

WIPtracker supports barcode and RFID for precise tracking, automating supply chain traceability via EPCIS or EDI files—ideal for FDA-regulated operations ensuring full audit trails as a Supply Chain Visibility & Traceability Platform.

Fragmented Order Management Across Systems

Challenge: Fragmented Order Management Across Systems

Customer orders from various sources lead to siloed data, inefficient procurement, manufacturing, and shipping—causing bottlenecks and poor visibility.

Solution: Unified Order Stream and DEX Database

Intelligent agents unify orders into a single stream, routing to ERP/engineering systems, WIPtrackers based on location/capacity, and distributing tracking data to BI tools via the central DEX Operations Management Database, serving as a robust Manufacturing Operations Management (MOM) Suite.

Inefficient Planning and Scheduling Leading to Delays

Challenge: Inefficient Planning and Scheduling Leading to Delays

Reactive planning based on outdated reports results in production bottlenecks, resource underutilization, and missed deadlines across multi-site operations.

Solution: Predictive Planning and Automated Scheduling with IAPs

Intelligent Agent Processes (IAPs) perform predictive planning, routine decision-making, and automated scheduling using Python scripts and prebuilt libraries—optimizing resources proactively and reducing delays by up to 90% in dynamic environments.

Limited Visibility and Reactive Decision-Making

Challenge: Limited Visibility and Reactive Decision-Making

Operations managers lack real-time insights into status and history across sites, relying on after-the-fact reports that hinder proactive problem detection and business intelligence.

Solution: Real-Time DEX Database and BI/AI Integration

The DEX Operations Management Database serves as a central repository for all order and tracking data, enabling direct BI/AI access via web services for interactive dashboards, problem detection, and decision support—transforming reactive ops into proactive intelligence.

Simplify Operations Tracking

WIPtracker IIoT boxes track work-in-process from receipt to shipping using barcode/RFID, with auxiliary support for label printing and scales. Compatible with wireless mobiles, PCs, and tablets via web browsers—no custom software needed.

Perfect for diverse operations, including remote farming/construction with offline syncing to the central database, empowering it as an Industrial Digital Transformation Platform.

Enhance Decision Support

The DEX database powers BI/AI applications for interactive insights, while IAPs (Intelligent Agent Processes) handle monitoring, analysis, alerts, and scheduling using Python scripts on prebuilt libraries—running 24×7 with remote IT monitoring, embodying an Intelligent Agent-Based Operations Platform.

Key Benefits

SmartOps24x7 delivers industrial organizations real-time tracking and management of jobs, materials, and workflows across manufacturing plants, distribution warehouses, delivery, field, and installation operations, slashing manual grunt work and boosting operational efficiency. Powered by intelligent agents and WIPtracker IIoT devices with barcode/RFID capture, store-and-forward syncing, and automated traceability, it eliminates paper forms, spreadsheets, and duplicate data entry while ensuring seamless ERP integration and regulatory compliance. Deployable in the cloud or on-premises with minimal setup, SmartOps24x7 provides instant visibility, predictive alerts, and scalable automation, empowering managers to detect issues proactively, optimize decisions, and drive maximum productivity and ROI through its central DEX database.

Prevent Costly Delays and Errors

Automate tracking and alerts to reduce manual errors by over 90%, ensuring real-time visibility and proactive issue resolution.

Scalable & Flexible

Deploy across single sites or multi-facility enterprises, integrating seamlessly with existing ERPs without complex setups—evolving with your needs via dynamic agents.

Expert Support

Smart Operations Management LLC provides libraries, interfaces, and support to customize agents quickly, maximizing ROI with minimal coding.

Ready to Transform Your Operations?

Experience the power of SmartOps24x7 with intelligent automation and real-time tracking.

Interested in Learning More?

Click the button below to access KnarrTek’s Whitepapers by Dr. Peter Green.

KnarrTek's Capabilities

Materials Flow & Job Tracking

Monitor material flow and job progress throughout production.