|

Software + Services + Expertise |

|

BellHawk is real-time container-based operations-tracking software which is used for work-in-process, operations and materials tracking in manufacturing plants and industrial warehouses.

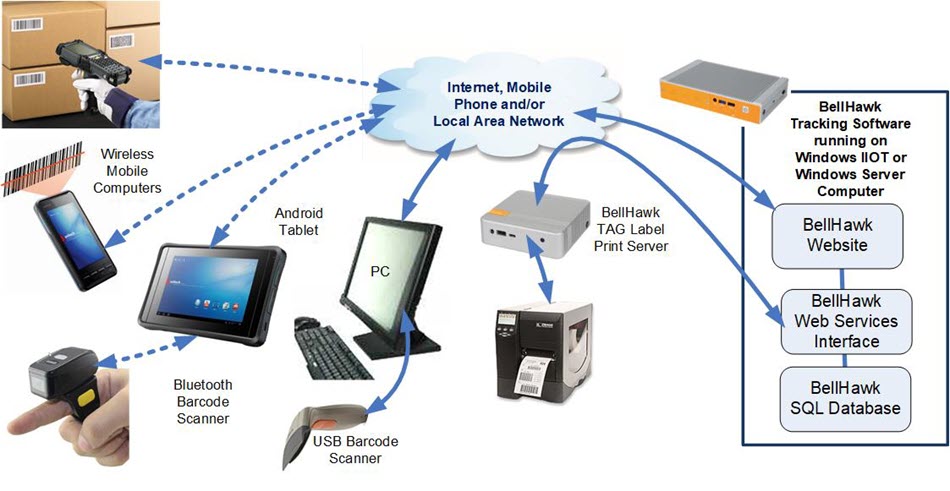

In its simplest form, a BellHawk based system consists of:

For users with simple inventory, asset, or production tracking requirements, BellHawk can be used on a subscription basis, in-the-Cloud, through KnarrTek's BellHawk Online service.

For most applications, BellHawk is run in a ruggedized Windows IIOT Enterprise based industrial computer as each site. This gives the best combination of reliability and performance at the lowest cost. Please click on Running BellHawk in an IIOT Box for more details.

Where appropriate, BellHawk can also be run on a dedicated (not shared) Windows Server computer in a client's own data center.

Please see the Technical Note Where to Run BellHawk in 2023 for a discussion of some of the trade-offs as well as the white paper From the Cloud to the Edge for Barcode and RFID Tracking" for a deeper dive into this subject.

BellHawk can be used on its own, with manual entry of receiving, work, pick/move, and ship orders or it can exchange data with a wide variety of other systems by means of the BellHawk MDEX Interface or by using KnarrTek's MilramX enterprise integration software platform . There is also a Remote Desktop Interface (RDI)which enables users to exchange data in the BellHawk database with a database on their desktop PCs for the purpose of generating custom reports or Excel exports.

BellHawk is designed for data capture by materials handlers, machine operators, and other production workers who

are not computer literate or for whom English is a second language. It does this by using Artificial Intelligence to

minimize the amount of data entry required, by leading the user step by step through data entry, and by only taking

in one entry at a time and then immediately checking the entry to warn the user if they are about to make an

operational or data entry mistake. This enables operations and inventory data to be captured in real-time with

minimal intervention by managers and supervisors.

In its simplest form, BellHawk does not need the use of barcode label printers as it can print out barcoded receiving order sheets, work order travelers, pick orders, and ship orders on office laser printers. BellHawk can also use rolls of pre-printed barcode labels for the purpose of tracking containers of material. But, where automated printing of situation specific barcode labels, with human readable information which is based on the contents of the BellHawk database, is required then the BellHawk TAG rules-based label printing solution should be used.

For more information about tracking materials and assets using RFID, please click on BellHawk Integrated Barcode and RFID Tracking Solution

Please click here to return to an Overview of the BellHawk Software.

| About KnarrTek | Technology |

|

Services | Cost Savings |

| Copyright © KnarrTek Inc. 2024 |

| Technology |

|

Services |

| About KnarrTek | Copyright © KnarrTek Inc. 2024 | Cost Savings |