|

Software + Services + Expertise |

|

BellHawk tracks when work starts and ends on operations, such as machining, test, and assembly operations. These operations are associated with the work centers where these operations are performed.

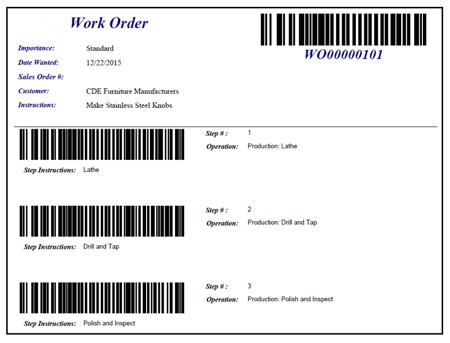

For tracking purposes, operations such as machining, testing, and assembly are associated with work orders, which themselves are typically related to customer orders but may also be for a wide variety of applications such as making intermediate materials or even maintenance and repair of equipment.

Work orders may have a route of expected operations associated with them, in which case it can be beneficial to print out a barcoded traveler. This traveler is scanned to record when each operation starts and finishes.

Work orders do not need to have a pre-established route of operations and, even when they do, out of route operations, such as for rework, can be scanned as part of the manufacturing process.

This same traveler can be used as the basis of work-in-process tracking, including capturing job cost and

materials traceability data.

BellHawk is simple to use and enables the rapid transition from the use of paper forms and manual keyboard data

entry to real-time barcode data collection and having real-time information about the status of customer

orders.

The BellHawk Operations Tracking solution, on its own, is ideal for use by make-to-order manufacturing plants that need a simple way to track the status of customer orders through a sequence of operations. It can also be used for maintenance, test, and repair operations as well as used as the basis for more complex tracking activities.

Please click here to return to the BellHawk Overview.

| About KnarrTek | Technology |

|

Services | Cost Savings |

| Copyright © KnarrTek Inc. 2024 |

| Technology |

|

Services |

| About KnarrTek | Copyright © KnarrTek Inc. 2024 | Cost Savings |