|

Software + Services + Expertise |

|

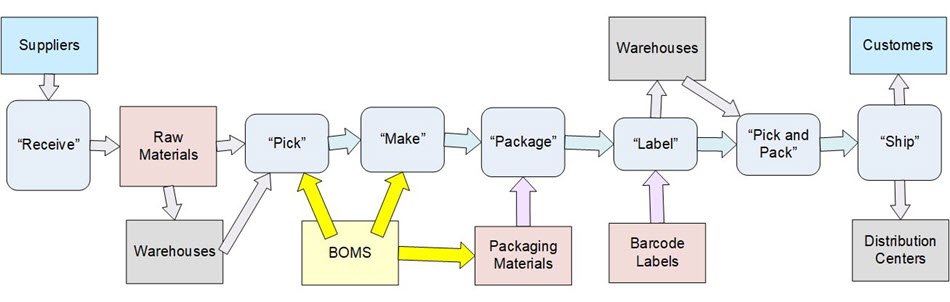

A KnarrTek Real-Time Materials Tracking and Decision Support (MTDS) system tracks:

KnarrTek MTDS systems typically make extensive use of License-Plate-Number (LPN) container tracking to track containers of material and serialized items. This is the same tracking method used by organizations such as Amazon, UPS, and FedEx. It is also the basis of the GS1 standard for tracking materials in the Global Supply Chain as well as traceability standards of organizations such as the FDA and ISO.

With LPN tracking, a uniquely numbered tracking barcode is attached to each container or serialized item that is to be tracked. This barcode is scanned whenever the container is moved to record its new location, as well as when materials are entered or withdrawn from the container.

The tracking barcodes are also scanned when materials are received, used or produced by manufacturing operations, as well as when they are picked, packed, and shipped. This enables real-time tracking of the locations of materials at all time, as well as enabling tracking of lot and serial numbers, as well as expiration dates and QC status of materials.

It also enables tracking of materials by project as well as separation of materials by project to make sure materials purchased for one project are not used on another. The Use of LPN tracking also enables tracking nested containers, such as pallets with many different materials, using a single tracking barcode on the pallet.

Please click here to learn more about The Materials Tracking and Traceability Capabilities of the KnarrTek MTDS Software.

| About KnarrTek | Technology |

|

Services | Cost Savings |

| Copyright © KnarrTek Inc. 2024 |

| Technology |

|

Services |

| About KnarrTek | Copyright © KnarrTek Inc. 2024 | Cost Savings |